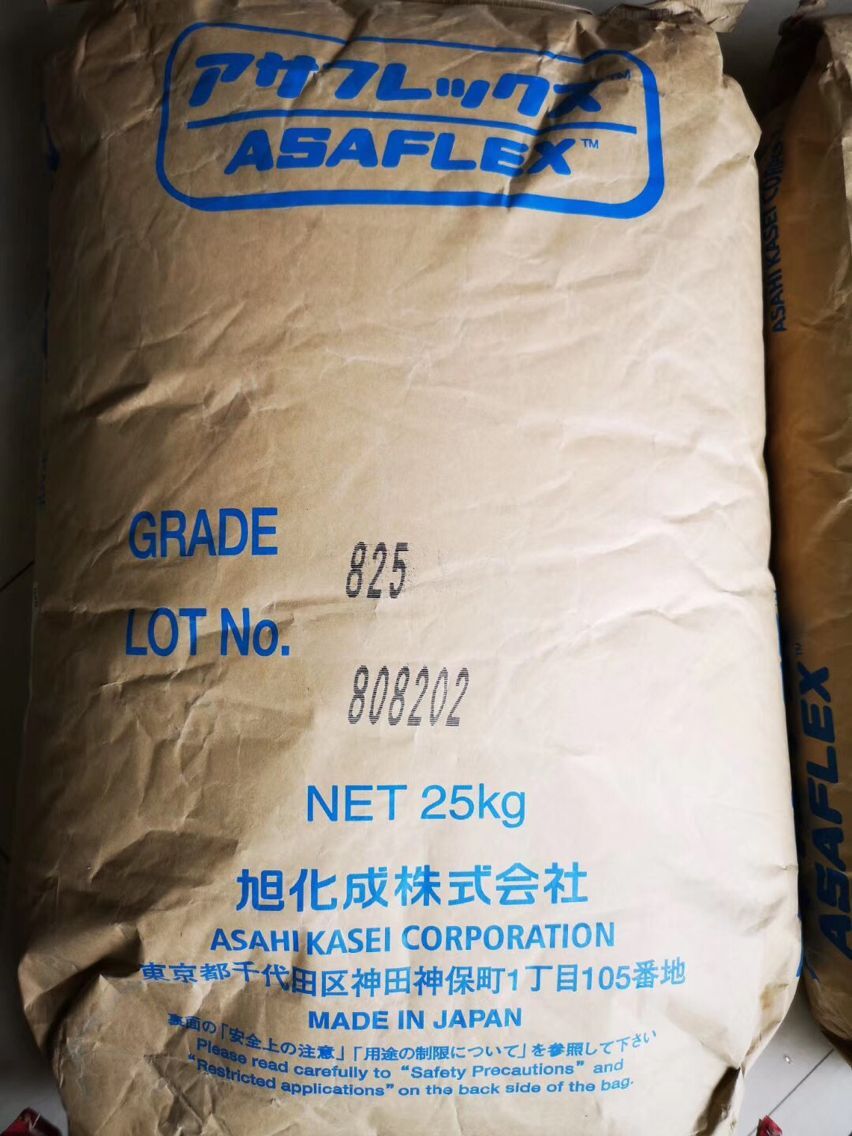

SBC Asaflex 815 K膠 日本旭化成 高透明

Clear Styrenic Block Copolymer (SBC) Asaflex? 815

Asaflex? 815 has a wax added grade to Asaflex 810. Well suited for deep-drawn packaging such as blister packaging.

Applications

- Food Packaging

- Polymer Modification

Physical Form

- Pellet

Features and Benefits

- Deep drawability

- High rigidity

- High impact resistance

Regulations

- FDA CFR 177.1640

- Regulation (EU) No 10/2011

Characteristics

| Property | Test Method | Unit | Value |

|---|---|---|---|

| Density | ISO 1183 | g/cm3 | 1.02 |

| Water Absorption | ISO 062 | % | <0.1 |

| MFR 200°C, 5kg Load | ISO 1133 | g/10 min | 6 |

| Mold Shrinkage | – | % | 0.2~0.8 |

| Tensile Strength, 50 mm/min | ISO 527-1 | MPa | 27 |

| Elongation, 50 mm/min | ISO 527-1 | % | 200 |

| Flexural Strength | ISO 178 | MPa | 37 |

| Flexural Modulus | ISO 178 | MPa | 1200 |

| Rockwell Hardness | ISO 2039-2 | – | HRR 55 |

| Durometer Hardness | ISO 868 | – | HDD 71 |

|

Charpy Impact Strength* Unnotched |

ISO 179 | kJ/m2 | 100 |

|

Charpy Impact Strength* V-notched |

ISO 179 | kJ/m2 | 2 |

|

Heat DistortionTemp. Non-annealed,1.8 MPa load, 120 K/h |

ISO 75-1 | °C | 57 |

|

Vicat Softening Point 10 N Load, 50 K/h |

ISO 306 | °C | 82 |

| Total Light Transmission, 2mm Thick Plate | ISO 13468 | % | 90 |

| Haze, 2mm Thick Plate | ISO 14782 | MPa | 0.5 |

*Value at fracture into two or more pieces

Please note that all data and values are given as typical results obtained with the indicated test methods for l,thpurposes of basic reference in grade selection only, and not as any product specification or warranty of any nature, and are subject to change without notice.

簡繁切換

簡繁切換