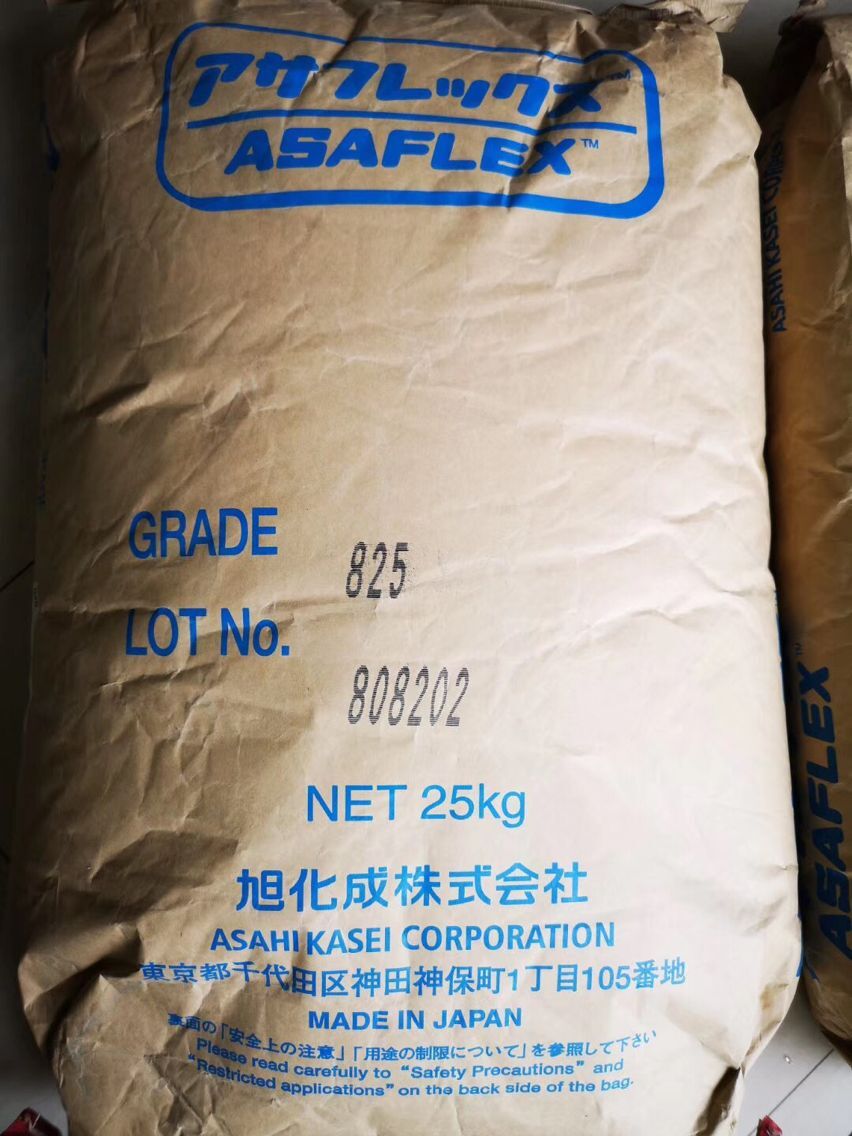

Clear Styrenic Block Copolymer (SBC) Asaflex? 800S

SBC 日本旭化成 800 高硬度Q膠

| Grade | MFR*1 |

Flexural Modulus |

Vicat Softening Point*2 |

Haze*3 | Applications |

|---|---|---|---|---|---|

| 800S | 6 | 2250 | 96 | 3.0 | Food PackagingMedicalTransparent Molded Products |

| 805 | 10 | 1550 | 91 | 0.5 | FootwearMedicalTransparent Molded Products |

| 810 | 5 | 1400 | 83 | 1.2 | Polymer ModificationAdhesives and SealantsFootwearTransparent Molded Products |

| 815 | 6 | 1200 | 82 | 0.5 | Food PackagingPolymer Modification |

| 825 | 6 | 1200 | 82 | 0.5 | Polymer ModificationFootwearTransparent Molded Products |

| 830 | 6 | 1100 | 72 | 2.0 | Polymer ModificationTransparent Molded Products |

| Property | Test Method | Unit | Value |

|---|---|---|---|

| Density | ISO 1183 | g/cm3 | 1.02 |

| Water Absorption | ISO 062 | % | <0.1 |

| MFR 200°C, 5kg Load | ISO 1133 | g/10 min | 6 |

| Mold Shrinkage | – | % | 0.2-0.8 |

| Tensile Strength, 50 mm/min | ISO 527-1 | MPa | 41 |

| Elongation, 50 mm/min | ISO 527-1 | % | 12 |

| Flexural Strength | ISO 178 | MPa | 54 |

| Flexural Modulus | ISO 178 | MPa | 2250 |

| Rockwell Hardness | ISO 2039-2 | – | HRR 78 |

| Durometer Hardness | ISO 868 | – | HDD 75 |

|

Charpy Impact Strength* Unnotched |

ISO 179 | kJ/m2 | 23 |

|

Charpy Impact Strength* V-notched |

ISO 179 | kJ/m2 | 1.1 |

|

Heat DistortionTemp. Non-annealed,1.8 MPa load, 120 K/h |

ISO 75-1 | °C | 69 |

|

Vicat Softening Point 10 N Load, 50 K/h |

ISO 306 | °C | 96 |

| Total Light Transmission, 2mm Thick Plate | ISO 13468 | % | 90 |

| Haze, 2mm Thick Plate | ISO 14782 | MPa | 3.0 |

簡繁切換

簡繁切換